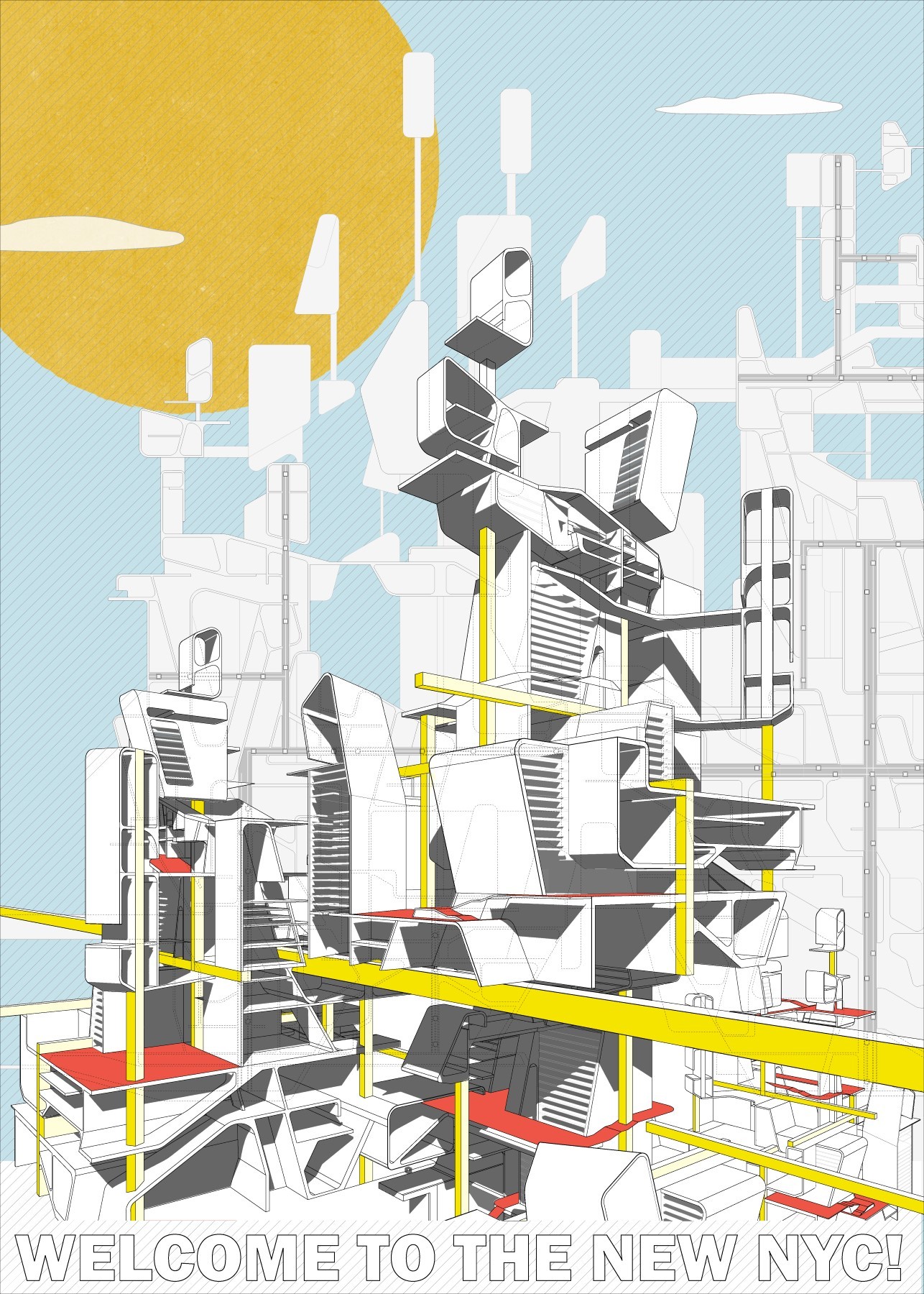

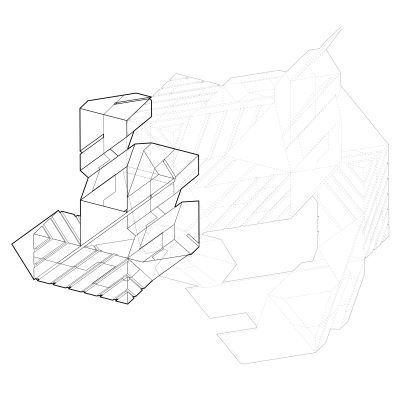

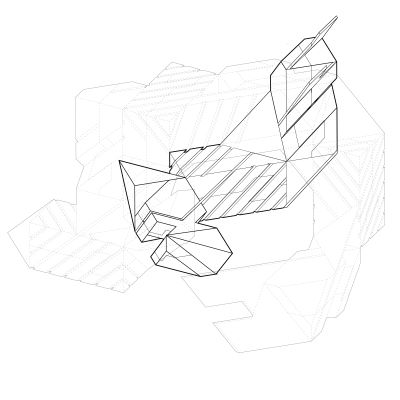

This project investigates how designers should engage contemporary advanced manufacturing techniques as a spectrum between extreme seamlessness where material properties are blended within multi-stream material blending in a single additive method to a highly customized assemblage of many parts where seams are made to appear and disappear for material attributes as well as emotional triggers.

DURATION

Jun 2019 - Aug 2019

PROJECT TYPE

Academic Project

MY ROLE

Student Designer

INSTRUCTOR

Jason Lee / Ajmal Aqtash

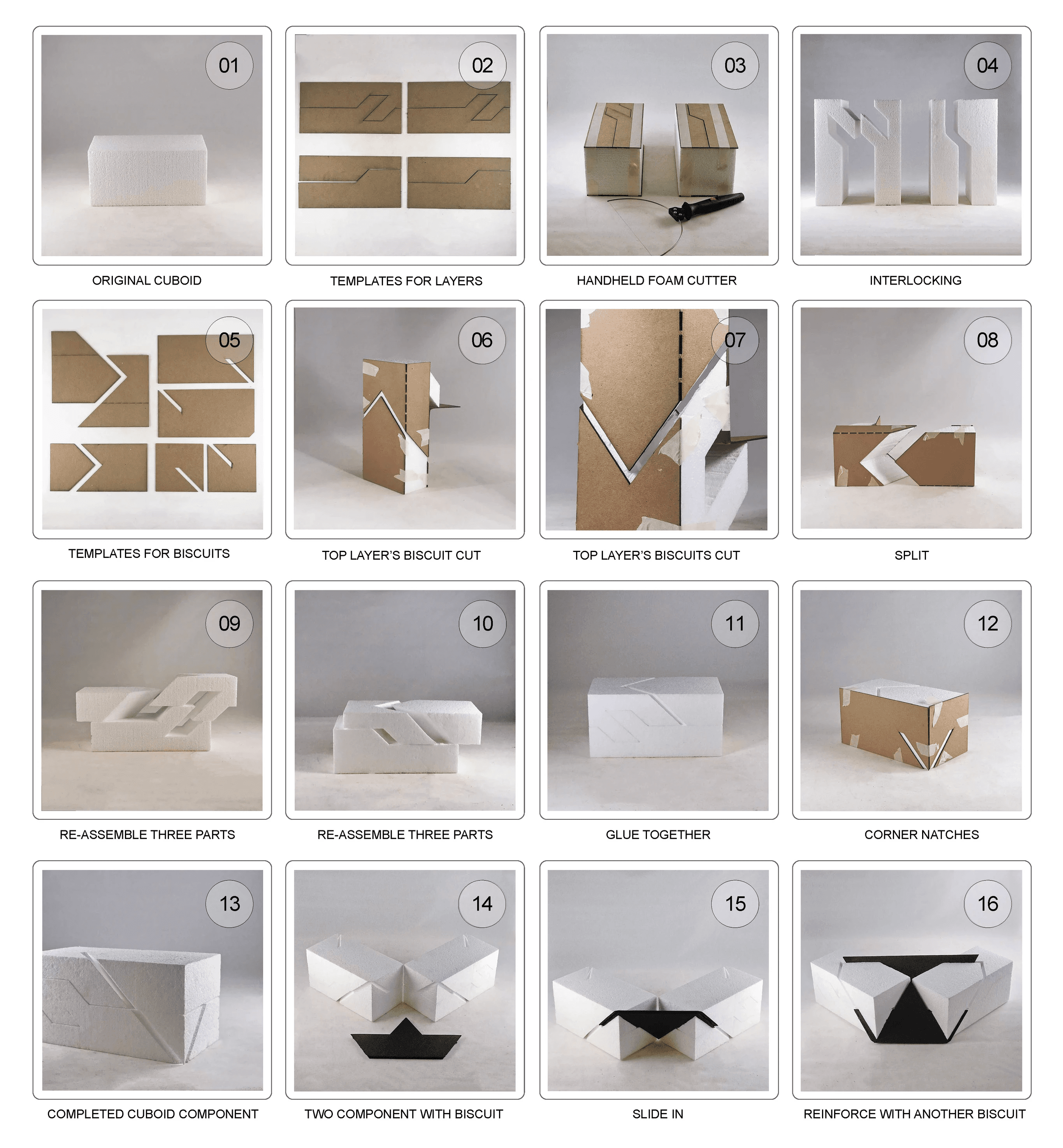

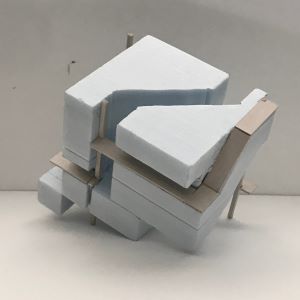

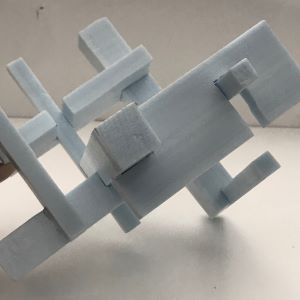

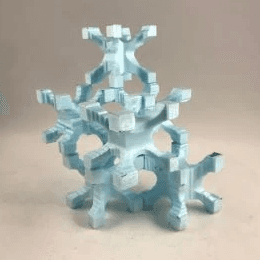

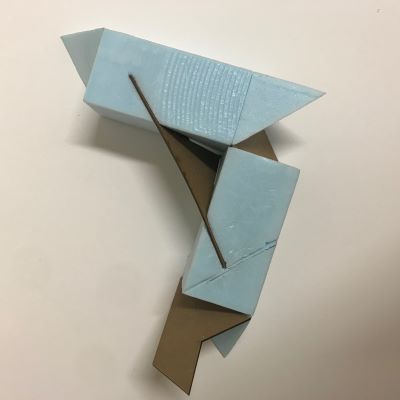

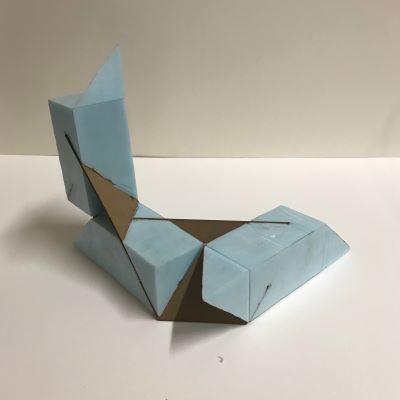

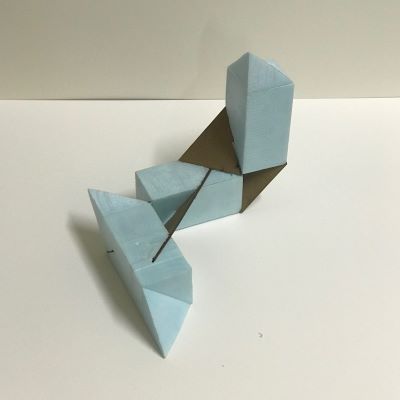

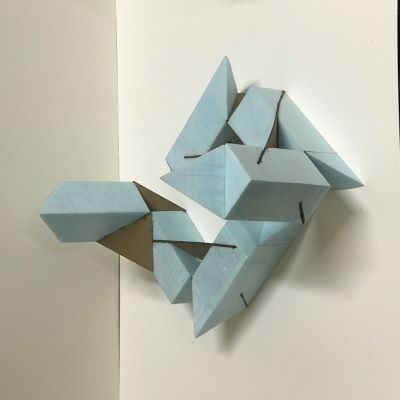

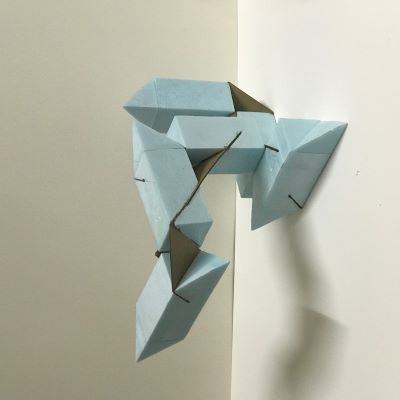

01 ASSEMBLAGE PROTOTYPING

During hands-on material production, the techniques typically provide live feedback that informs the design process so that the formal tectonics relationship is often informed by physical material constraints and properties. Attempting to explore new forms of feedback between methods and materials can help inform new design agendas.

02 MATERIAL TESTING & PROTOTYPING

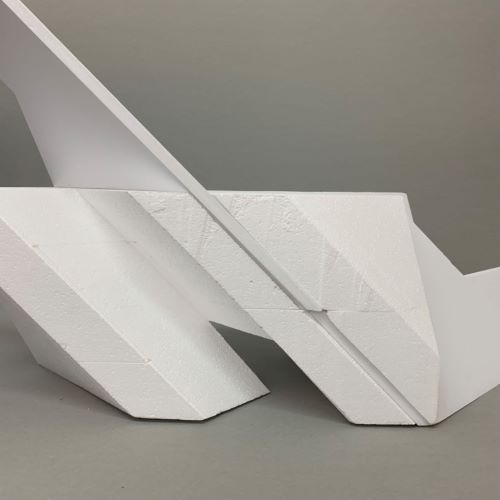

The fifth assemblage above was chosen for further prototyping. The seams integrate into the geometry and create visual effects that give the appearance of perfect continuity.

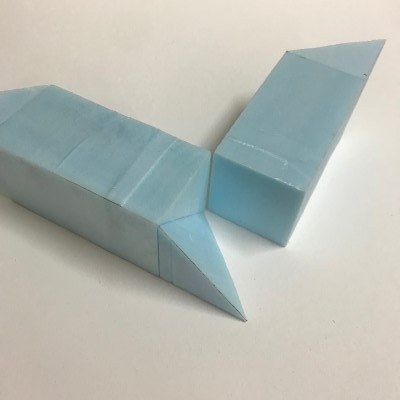

PROTOTYPE 1

FOAM + CHIPBOARD

Pros: light weight, easy to cut

Cons: not enough friction to hold tightly

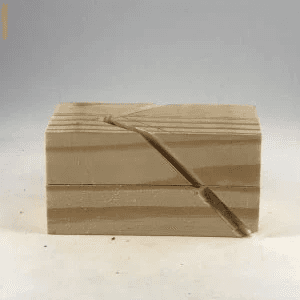

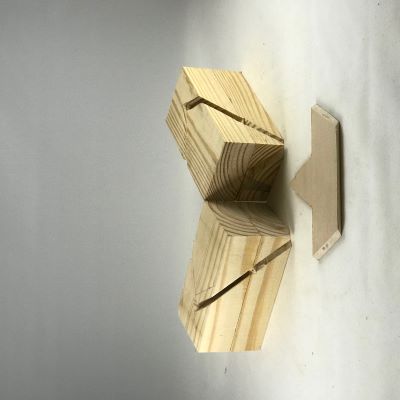

PROTOTYPE 2

SOLID WOOD + WOOD CHIP

Pros: solid and last

Cons: hard to cut, too heavy

PROTOTYPE 3

STYROFOAM + FOAM CORE

Pros: light weight, easy to cut, enough friction to hold tightly

Cons: not solid and last

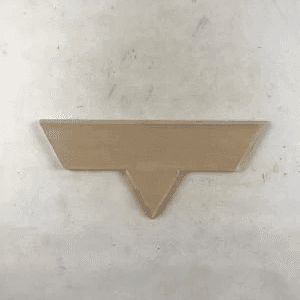

03 PRODUCTION WORKFLOW

WORKFLOW MOCK-UP

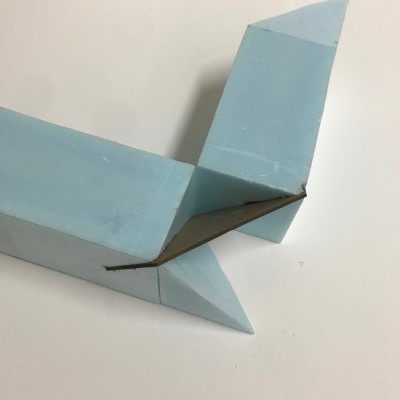

Solid Styrofoam and foam core board have been chosen for the final production, thanks to their lightweight properties and excellent frictional performance. To streamline production, the development of an efficient workflow handbook is crucial. In the studio, a small-scale mock-up workflow has been tested using a handhold foam cutter and laser-cut chipboard guides.

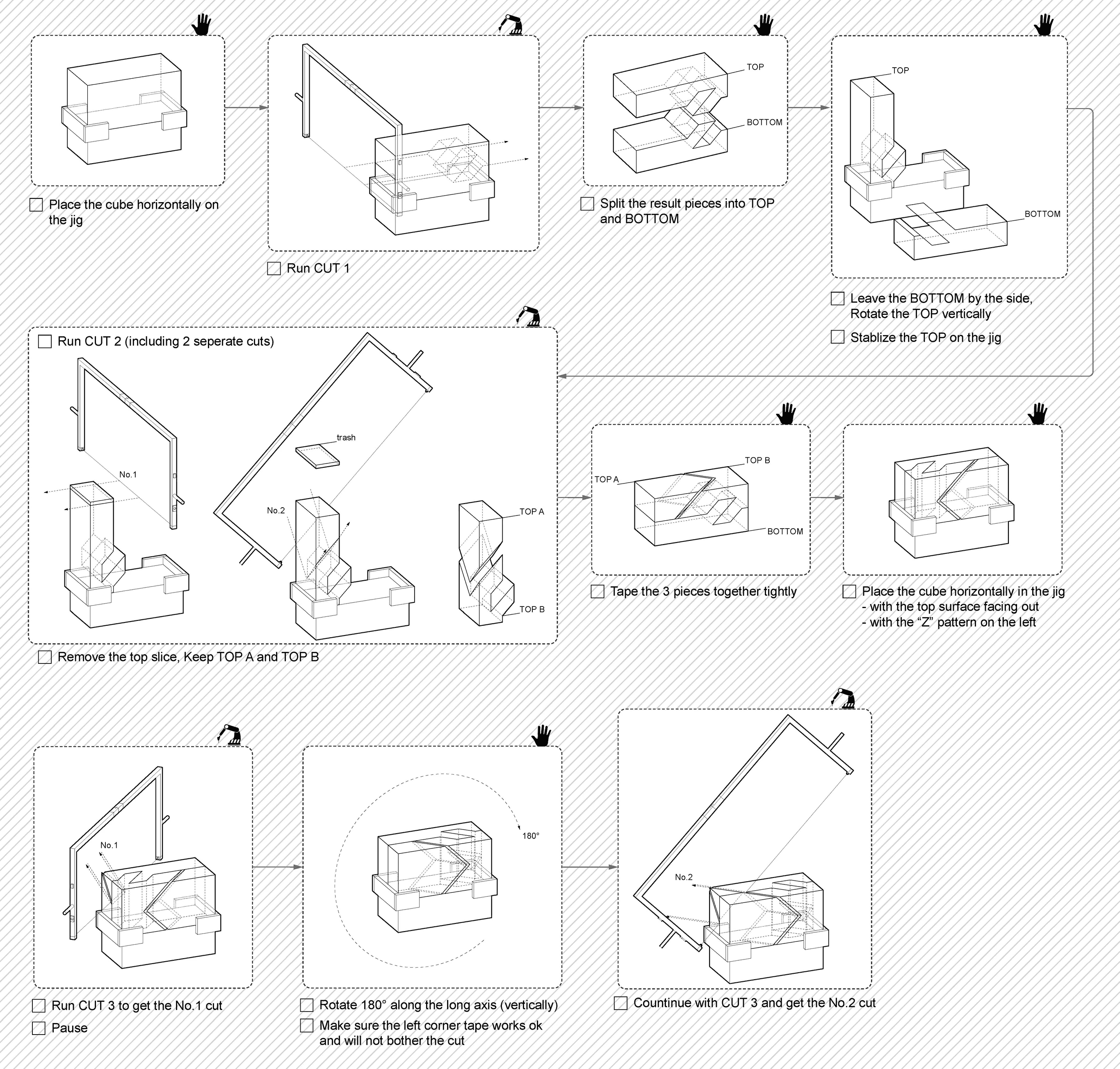

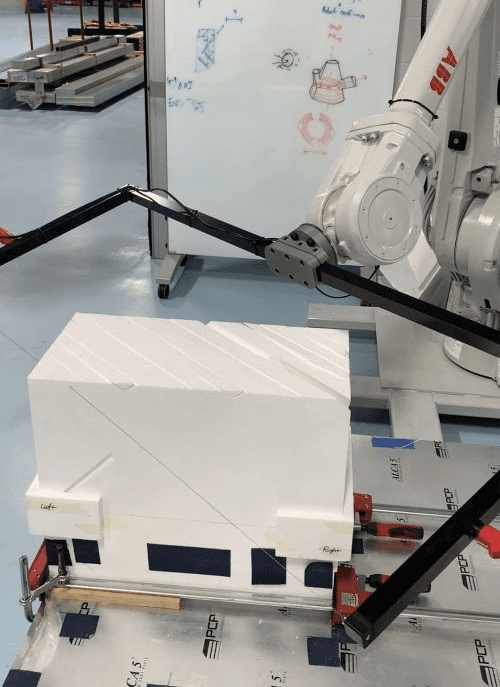

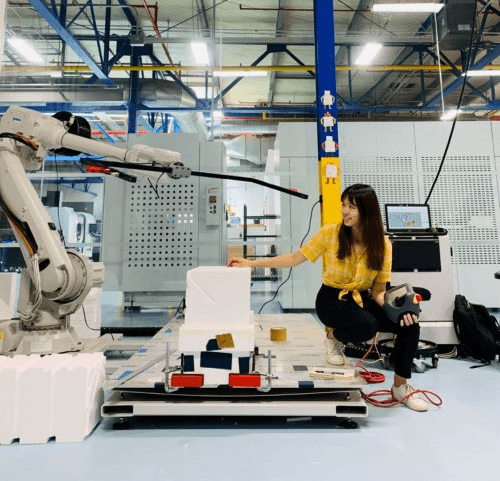

PROGRAMMING THE ROBOT

TACO ABB, a programming plugin for Rhino, is employed to code the “Carve Out” and “Stripe Pattern” motions for the ABB robot.

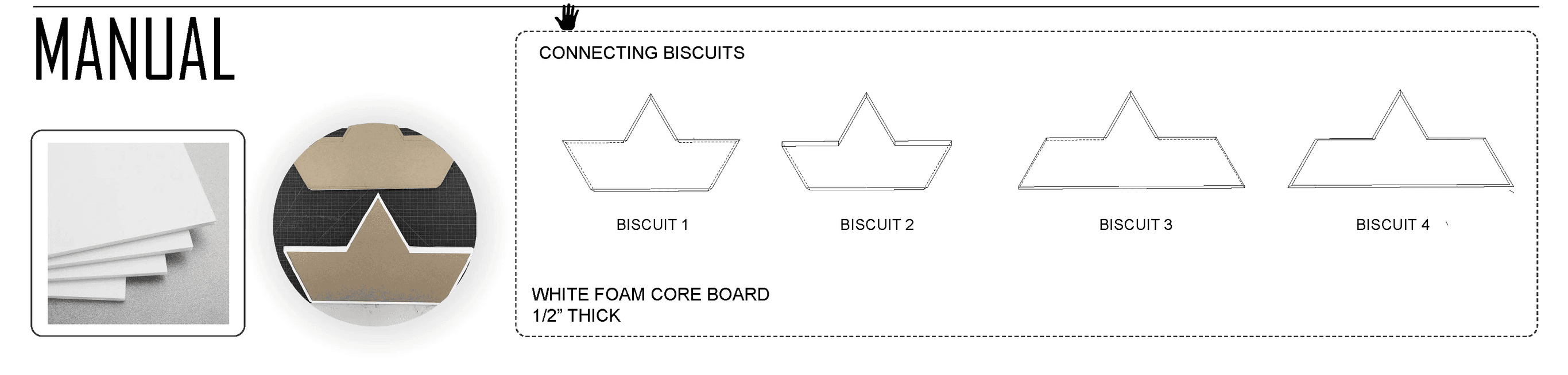

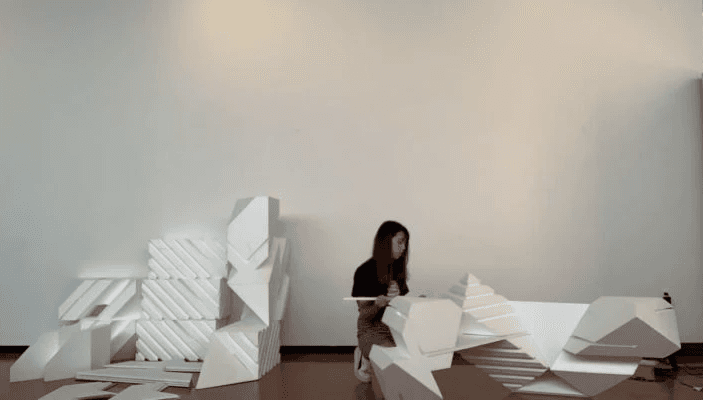

PRODUCER’S HANDBOOK

Given the intricacy of this multifaceted production process, involving a combination of manual and robotic actions, a comprehensive producer’s handbook and checklist have been crafted. By methodically adhering to and marking each step, I successfully executed the cutting of over 20 full-scale pieces with precision and efficiency.

04 PRODUCTION

FULL-SCALE COMPONENTS

12"x12"x24" Styrofoam Cube and Foam Core Board

05 ASSEMBLE PROCESS

06 FINAL OUTCOME

VIEW OTHER PROJECTS